Small scale palm kernel oil refinery plant

Factory direct sale contact number

Small scale palm kernel oil refinery plant introduction:

Basing on the traditional oil refining technology, our company has developed the latest palm kernel oil refinery plant. Moreover, a series of advanced technology and equipment are used in palm kernel oil refinery plant, such as super wet deguming, bleaching earth automatic metering, negative pressure decoloring, high vacuum steam jet deodorization, deacidification, winterization dewaxing etc. With advanced technology, superior equipment, full-automatic control and excellent economic and technical parameters, our small scale palm kernel oil refinery plant can meet customers’ different refining requirements at home and abroad.

2tpd palm kernel oil refinery plant

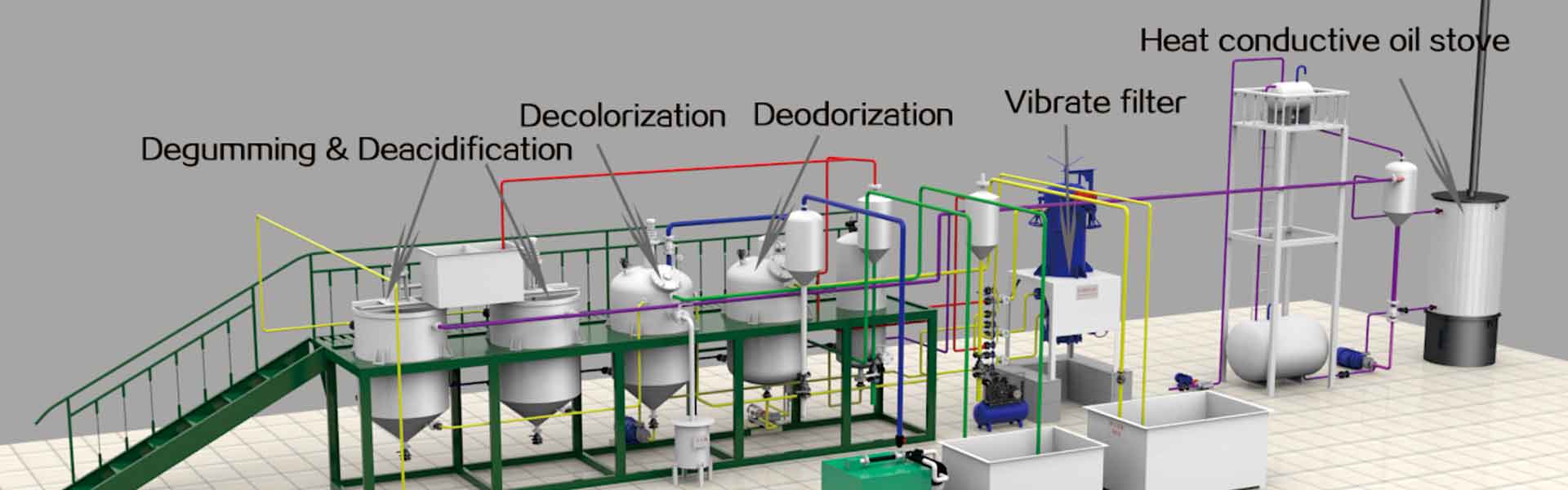

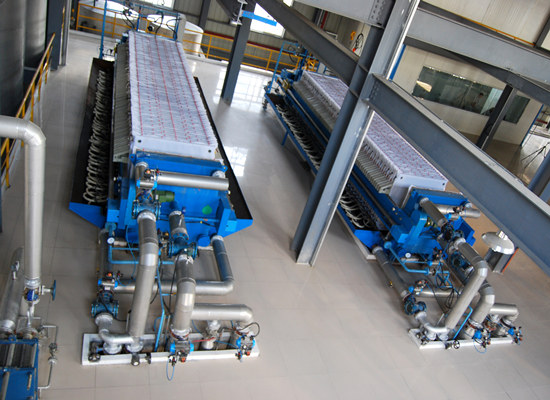

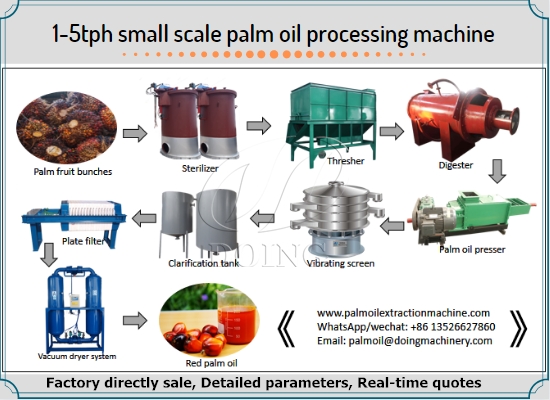

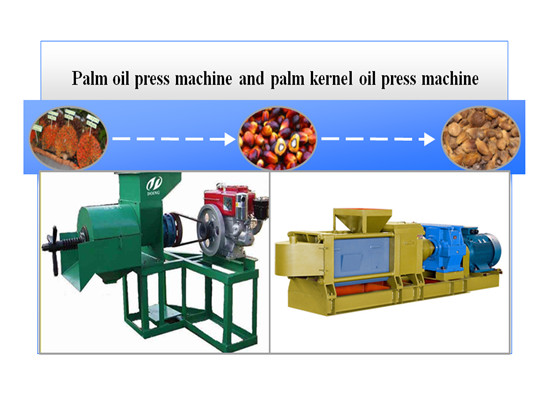

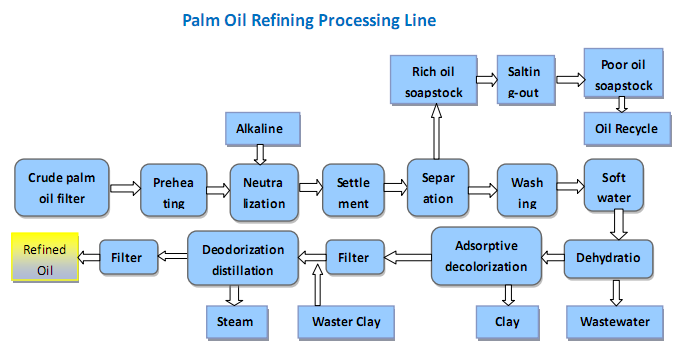

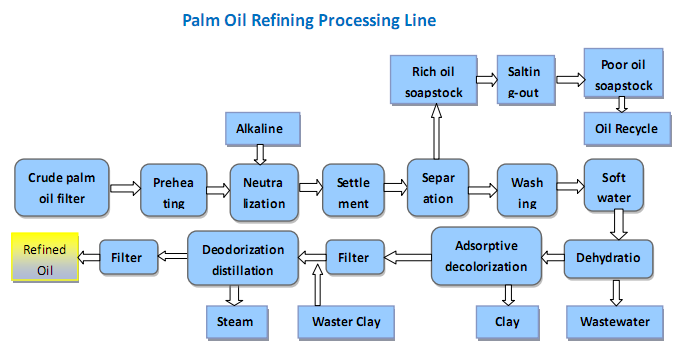

Small scale palm kernel oil refinery plant flow chart:

Palm oil refining processing line(Palm kernel oil refining process is the same with palm oil refining process)

Small scale palm kernel oil refinery process:

Degumming and Deacidification Section:Palm kernel oil degumming and deacidification section uses washing method to separate soap residual from mixing oil, providing preparation for next step palm kernel oil refinery plant.

Decolorizing Section:Palm kernel oil decolorizing section is mainly used to remove oil pigment, residual soap and metal ions during palm kernel oil refinery process.

Deodorization Section:Palm kernel oil deodorization section composes of part of crude palm kernel oil refinery plant. It plays important part in improving oil quality after crude palm kernel oil process.

Small scale palm kernel oil refinery plant

Featured advantages of small scale palm kernel oil refinery plant:

◆Advanced crude palm kernel oil refinery plant configuration and precise equipment manufacturing

◆Automatic control system

◆Excellent technical and economical indicators

◆Meeting customers’ different palm kernel oil refinery plant requirements at home and abroad

◆Palm kernel oil refinery plant covers entire processing line of degumming and deacidification, blenching, deodorization and fractionation.

Note: Small scale palm oil refining machine 3D animation video

With Over 40 years/ experience of designing & installing & exporting complete oil refinery plant like vegetable oil refinery, we are now the leading company in edible / cooking oil refinery field. We supply various edible /cooking oil refinery plant and technology to ensure that best finished oil is achieved with the lowest production cost. If you'd like to get more information about our small scale palm kernel oil refinery plant, please don't hesitate to contact us. We are always at your service.

Basing on the traditional oil refining technology, our company has developed the latest palm kernel oil refinery plant. Moreover, a series of advanced technology and equipment are used in palm kernel oil refinery plant, such as super wet deguming, bleaching earth automatic metering, negative pressure decoloring, high vacuum steam jet deodorization, deacidification, winterization dewaxing etc. With advanced technology, superior equipment, full-automatic control and excellent economic and technical parameters, our small scale palm kernel oil refinery plant can meet customers’ different refining requirements at home and abroad.

2tpd palm kernel oil refinery plant

Small scale palm kernel oil refinery plant flow chart:

Palm oil refining processing line(Palm kernel oil refining process is the same with palm oil refining process)

Small scale palm kernel oil refinery process:

Degumming and Deacidification Section:Palm kernel oil degumming and deacidification section uses washing method to separate soap residual from mixing oil, providing preparation for next step palm kernel oil refinery plant.

Decolorizing Section:Palm kernel oil decolorizing section is mainly used to remove oil pigment, residual soap and metal ions during palm kernel oil refinery process.

Deodorization Section:Palm kernel oil deodorization section composes of part of crude palm kernel oil refinery plant. It plays important part in improving oil quality after crude palm kernel oil process.

Small scale palm kernel oil refinery plant

Featured advantages of small scale palm kernel oil refinery plant:

◆Advanced crude palm kernel oil refinery plant configuration and precise equipment manufacturing

◆Automatic control system

◆Excellent technical and economical indicators

◆Meeting customers’ different palm kernel oil refinery plant requirements at home and abroad

◆Palm kernel oil refinery plant covers entire processing line of degumming and deacidification, blenching, deodorization and fractionation.

Note: Small scale palm oil refining machine 3D animation video

With Over 40 years/ experience of designing & installing & exporting complete oil refinery plant like vegetable oil refinery, we are now the leading company in edible / cooking oil refinery field. We supply various edible /cooking oil refinery plant and technology to ensure that best finished oil is achieved with the lowest production cost. If you'd like to get more information about our small scale palm kernel oil refinery plant, please don't hesitate to contact us. We are always at your service.

Leave A Message

If you want to know more information about Small scale palm kernel oil refinery plant . pls kindly leave your phone number, We will back to you ASAP once we got your message.

Palm kernel oil refinery

Products

palm oil mill plant projects

Palm Oil Extraction FAQ

-

How to start a palm oil milling and processing plant?

How to start a palm oil milling and processing plant?

-

How to start a palm oil processing business in nigeria?

How to start a palm oil processing business in nigeria?

-

How to produce refined vegetable oil from palm kernel oil?

How to produce refined vegetable oil from palm kernel oil?

-

What are the steps in palm oil production?

What are the steps in palm oil production?

-

Analysis of investment cost of small and medium-sized palm oil production lines

Analysis of investment cost of small and medium-sized palm oil production lines

-

What after-sales support, maintenance services and training can Henan Glory provide customers with for palm oil extraction machines?

What after-sales support, maintenance services and training can Henan Glory provide customers with for palm oil extraction machines?

-

What is required to set up a palm oil manufacturing plant?

What is required to set up a palm oil manufacturing plant?

-

Skid-mounted palm oil production unit

Skid-mounted palm oil production unit

recommend products