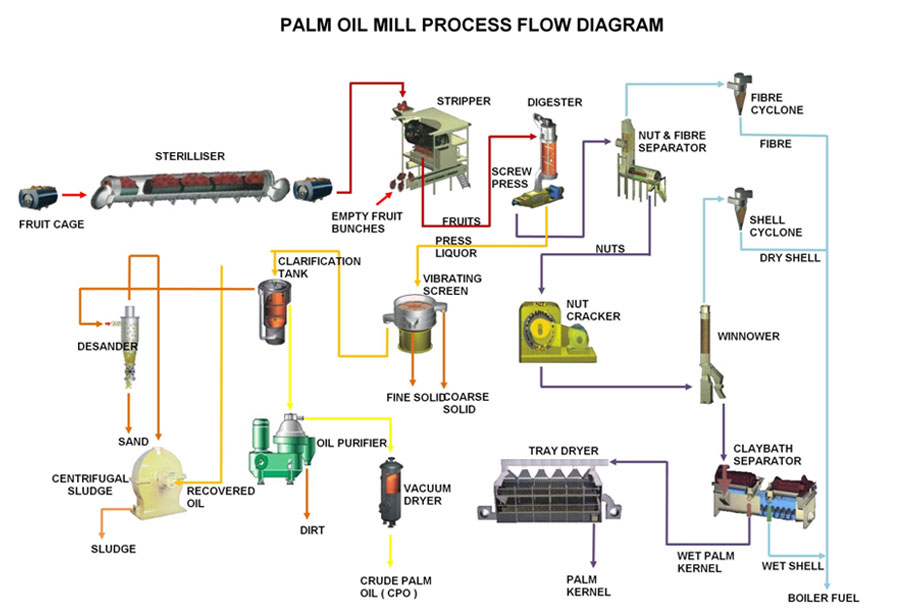

Palm oil mill process

Figure 1: Crude palm oil is extracted from oil palm by palm oil mill process machinery

Figure 1: Crude palm oil is extracted from oil palm by palm oil mill process machinery

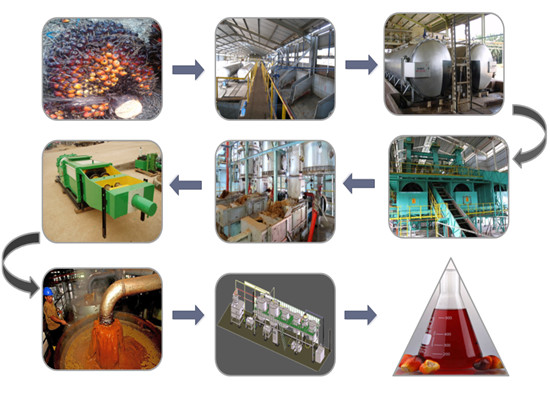

Palm oil mill process is quite different from other oil seeds processing. Palm oil mill process includes 6 parts: Palm fruits receiving, sterilizing, threshing, digesting and pressing, crude oil clarifying and palm kernel recovery.Our palm oil mill process is low cost and energe-saving.

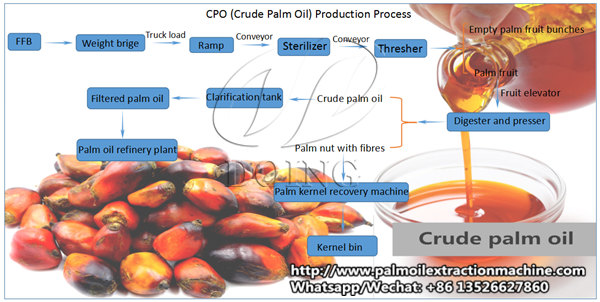

Figure 2: Each station of palm oil mill plant

Figure 2: Each station of palm oil mill plant

Palm oil is extracted from fresh fruit bunches (FFB) by a mechanical process, where a palm oil mill plant commonly handles 60-100tph of FFB.

A typical palm oil mill has many operational units as shown in Figure 2. This comprises of sterilization, threhsing, digesting and pressing, clarification, purification, drying and storage. For the palm kernel oil production line, there are steps such as nut/fiber separation, nut conditioning and cracking, cracked mixture separation, and kernel drying and storage. The dried kernels are often sold to palm kernel crushers for extraction of crude palm kernel oil. In some integrated plants, kernel crushing facilities exist side by side in the same complex.

Production capacity: 60-120TPH

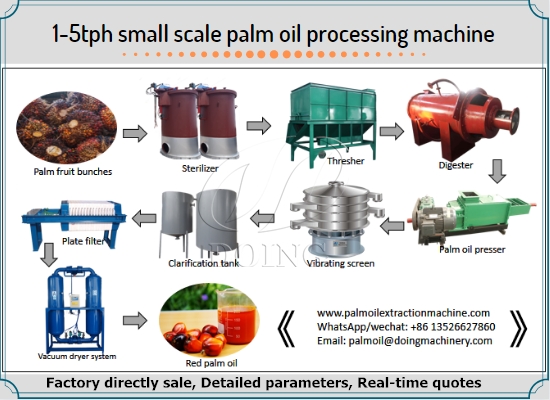

Work flow of palm oil mill process:

Figure 3: Palm oil mill process workflow

Figure 3: Palm oil mill process workflow

Palm oil mill process flow chart as follows:

Large-scale palm oil mill plants, featuring all stages required to produce palm oil to international standards, are generally handling from 60 to 120 tonnes of FFB/hr. The large installations have mechanical handling systems (bucket and screw conveyers, pumps and pipelines) and operate continuously, depending on the availability of FFB. Flow chart of the palm oil mill process is shown as follows:

Palm oil mill process flow chart ( click here to view larger diagram)

Palm oil mill process flow chart ( click here to view larger diagram)

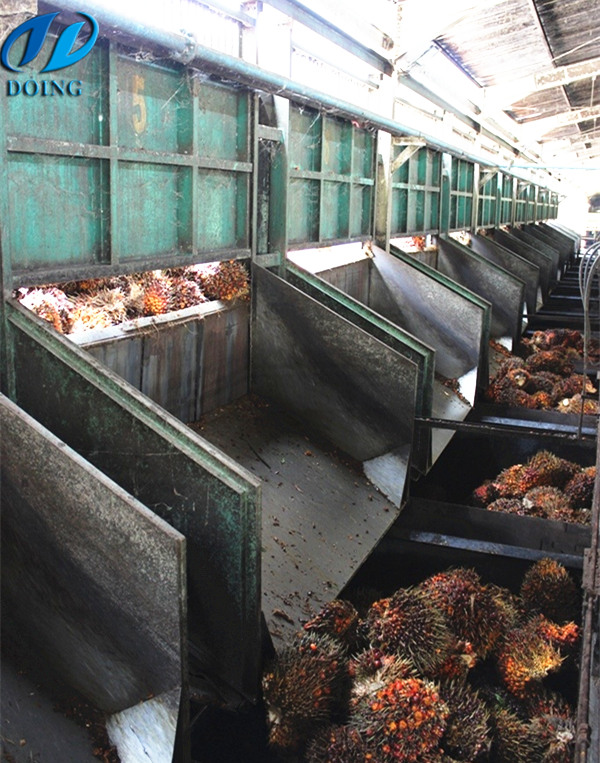

1.Raw material reception:

As for the first step of palm oil mill process,collecting the FFB and convey by trucks, then pour the fluster into the discharge door after weighed.

Figure 4: Palm fruit reception station

Figure 4: Palm fruit reception station

2.Sterilization:

FFB are airtight sterilized in sterilizer of palm oil mill process, the purpose is to prevent enzymes broken down, avoiding FFA content in oil further increase.

Figure 5: Horizontal type palm fruit sterilization machine

Figure 5: Horizontal type palm fruit sterilization machine

3.Threshing:

The purpose of threshing in the palm oil mill process is to separate the palm fruit from the FFB. The drum type thresher is the usual machine to separate the fruit.

Figure 6: This picture is drum type palm fruit threshing machine

Figure 6: This picture is drum type palm fruit threshing machine

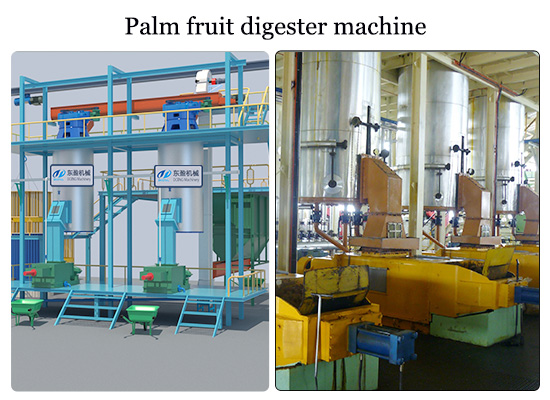

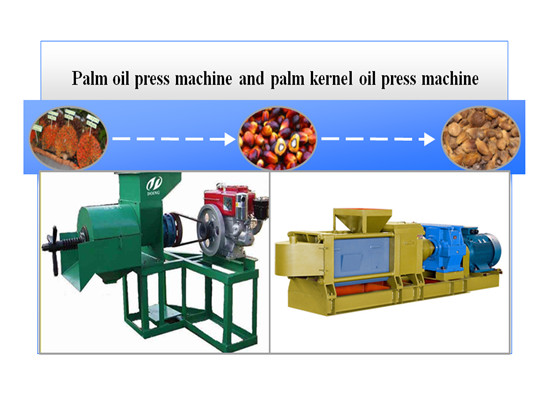

4.Digesting and pressing:

The purpose of digesting in the palm oil mill process is to separate the pulp and nut and crush the palm pulp. Then it is sent to continuous screw press. After pressing of palm oil mill process, oil palm fruit is divided into two parts: the mixture of oil, water and solid impurities, and the press cake (fiber and nut).

Figure 7: Palm fruit digesting and pressing machine

Figure 7: Palm fruit digesting and pressing machine

5.Oil clarification:

As for the oil clarification of palm oil mill process,oil is clarified by the vibrate screen.

Figure 8: Crude palm oil clarification machine

Figure 8: Crude palm oil clarification machine

6.Kernel recovery:

As for the last step of palm oil mill process, The separated fiber material is sent to the boiler room as fuel; the separated kernel is transported to kernel warehouse by pneumatic conveying system for temporary storage.

Figure 9: Palm kernel recovery station

Figure 9: Palm kernel recovery station

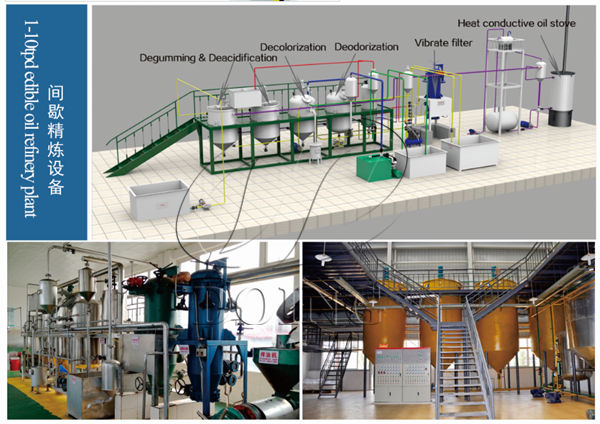

We will choose the palm oil mill process according to the different requirements of different customers. Both technical and economic effects are taken into account while plan the palm oil mill process, so that to build the best palm oil mill plant, Henan Doing Company is your best choice. After processed through the palm oil mill process,the crude palm oil can be sold or deeply processed. The next station of palm oil mill process is palm oil refinery process:

Palm oil refinery is an essential process for a complete palm oil mill plant because there are still some impurities such as phospholipids, FFA, pigment, odor,etc. in the crude palm oil. Henan Doing Mechanical Equipment Co.,Ltd, as a professional palm oil refinery manufacturer who is devoted to processing pure edible oil for worldwide customers. We can provide professional technical support and first class palm oil refinery plant and other palm oil machine for customers.

In general, palm oil refinery plant devides to 3 types: batch palm oil refinery plant, semi-continuous palm oil refinery plant, continuous plam oil refinery plant. These 3 oil refinery plants are used for different capacity. But the processes in each oil refinery plant are almost the same.

Batch type palm oil refinery plant

Batch type palm oil refinery plant

Semi-continuous palm oil refinery plant

Semi-continuous palm oil refinery plant

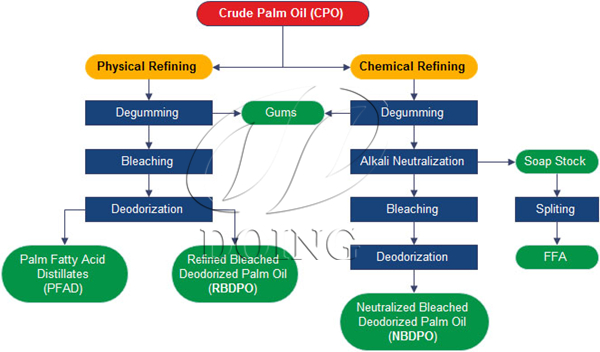

Palm oil refining process as follows:

Palm oil refining process diagram

Palm oil refining process diagram

Main Steps of palm oil refinery:

1.Degumming.

In this step gums in crude oil are removed by hydration with the help of phosphoric acid. Degumming is the first step for the whole palm oil refinery process.

2.Neutralization

In this step free fatty acids are neutralized by using sodium hydroxide and convert them into soap. Additional impurities are also removed by adsorption on soap.Neutralization is also called deacidification, it is the important part for palm oil refinery.

3. Bleaching

During bleaching, unwanted pigments are adsorbed physically and oil will become much clearer. Bleaching is also decolorization in palm oil refinery.

4. Deodorization

Deodorization is used to remove unacceptable odors by steam distillation, the odoriferous compound are stripped off with the help of live injected steam into heated oil under high vacuum pressure. Deodorization is mainly for making oil color lighter during palm oil refinery process. Which can make oil looks good.

We are experienced in building palm oil refinery plant, palm kernel oil refinery plant and palm oil extraction machine. View our website to find detailed information about palm oil processing plant, palm kernel oil processing plant, other related oil mill machinery. Want to start your palm oil business and build a customized, palm oil refinery plant with low investment? Henan Doing Company should be your best choice! Believe it or not, Henan Doing Mechanical equuipment Co., Ltd. supply various kinds of palm oil machine as follows:

1-10tph small scale palm fruit processing plant;

15-45tph medium scale palm fruit processing plant;

60-120tph large scale palm fruit processing plant;

1-1000tpd palm kernel oil processing plant;

1-600tph palm oil and palm kernel oil refinery & fractionation plant;

Henan Doing Company, the top-rated palm oil mill plant supplier in China, has gained rich experience to provide the best palm oil processing plant in Nigeria. We boasts professional design and development team to customize the advanced palm oil processing machines and techniques for our Nigeria customers. Believe it or not, there, you will enjoy the first-class service and premium quality machines. You are welcomed to contact us for more detailed information about the palm oil processing plant and palm kernel oil making machine. We will offer you the specific list of palm oil mill process machinery and quote the latest cost of palm oil processing mill.

Leave A Message

If you want to know more information about Palm oil mill process . pls kindly leave your phone number, We will back to you ASAP once we got your message.

-

How to start a palm oil milling and processing plant?

How to start a palm oil milling and processing plant?

-

How to start a palm oil processing business in nigeria?

How to start a palm oil processing business in nigeria?

-

How to produce refined vegetable oil from palm kernel oil?

How to produce refined vegetable oil from palm kernel oil?

-

What are the steps in palm oil production?

What are the steps in palm oil production?

-

Three Small Machines That Double Your Palm Oil Production: Low-Cost Upgrade!

Three Small Machines That Double Your Palm Oil Production: Low-Cost Upgrade!

-

Why Nigeria palm oil producers prefer modular palm oil production system?

Why Nigeria palm oil producers prefer modular palm oil production system?

-

What is the working principle of vacuum dryer in palm oil mill?

What is the working principle of vacuum dryer in palm oil mill?

-

The role of clarification tanks in high-quality palm oil production

The role of clarification tanks in high-quality palm oil production