Crude palm oil refining process and refining purpose introduction

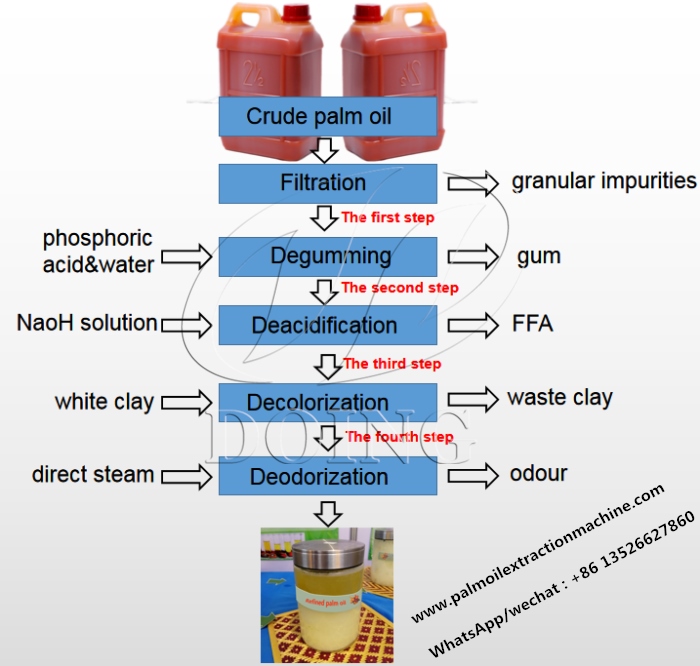

Crude palm oil refining generally refers to the process of removing impurities in crude palm oil and improving the purity of final vegetable oil. The existence of impurities in crude palm oil not only affects the edible value and safe storage of oil, but also brings difficulties to palm oil deep processing. The refining process of crude palm oil can be divided into four process steps: hydration degumming, alkali refining deacidification, adsorption decolorization and high temperature deodorization. [Related reading: Palm oil refining machine types and their characteristics ]

Crude palm oil refining process

Crude palm oil refining process

Hydration degumming is to separate the peptizing impurities in the crude oil. Its working principle utilizes the hydrophilicity of peptized impurities to add an appropriate amount of warm water to the crude oil and stir to make it absorb water and aggregate into agglomerates.

Alkali refining deacidification is to separate the free fatty acids in the crude oil, reduce the acid value of the oil, and avoid rancidity of the oil during long-term storage. Using the principle of acid-base neutralization, add an appropriate amount of stirring to the crude oil to make it react to form saponins. After precipitation and washing, the free fatty acids in the crude oil can be fully separated, and the acid value can be controlled within an appropriate range.

Adsorption decolorization is to separate the pigments contained in the crude oil, some of which are carried by the oil itself, and some new pigments produced in the production. Activated clay is usually used for adsorption and decolorization. Activated clay has strong adsorption capacity and can adsorb a variety of pigments and small molecular impurities.

High temperature deodorization is to separate the odorous substances in the crude oil and improve the flavor and taste of the oil. Steam is introduced into the crude oil under vacuum conditions, and the unpleasant odor in the crude oil is separated by utilizing the different volatility of grease and odorous substances.

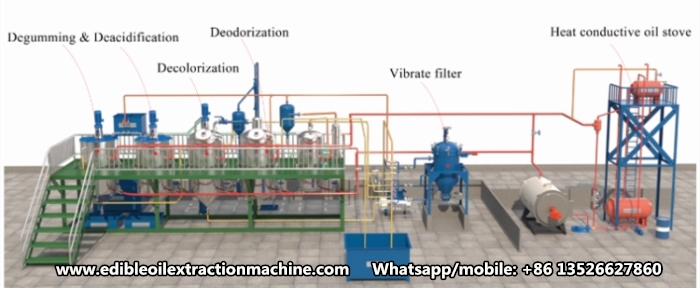

Main components of small scale palm oil refining machine

Main components of small scale palm oil refining machine

Refining is an important barrier for the quality assurance of edible oil. Usually, after the above four palm oil refining steps, most of the impurities in the crude oil can be better separated, and the obtained edible oil can basically meet the standard of qualified oil, but the specific situation is still Subject to actual production.

PREV:How to refine palm oil to RBD palm oil? What is the detailed refining processes of palm oil?

PREV:How to refine palm oil to RBD palm oil? What is the detailed refining processes of palm oil?

NEXT:Palm oil refining machine types and their characteristics

NEXT:Palm oil refining machine types and their characteristics

Leave A Message

If you want to know more information about Crude palm oil refining process and refining purpose introduction . pls kindly leave your phone number, We will back to you ASAP once we got your message.

-

How to start a palm oil milling and processing plant?

How to start a palm oil milling and processing plant?

-

How to start a palm oil processing business in nigeria?

How to start a palm oil processing business in nigeria?

-

How to produce refined vegetable oil from palm kernel oil?

How to produce refined vegetable oil from palm kernel oil?

-

What are the steps in palm oil production?

What are the steps in palm oil production?

-

What are the advantages of diesel palm oil presser compared to motor palm oil presser?

What are the advantages of diesel palm oil presser compared to motor palm oil presser?

-

How to optimize palm kernel crushing rate?

How to optimize palm kernel crushing rate?

-

Three Small Machines That Double Your Palm Oil Production: Low-Cost Upgrade!

Three Small Machines That Double Your Palm Oil Production: Low-Cost Upgrade!

-

Why Nigeria palm oil producers prefer modular palm oil production system?

Why Nigeria palm oil producers prefer modular palm oil production system?