What is the difference between a batch refinery, semi-continuous refinery, and continuous refinery?

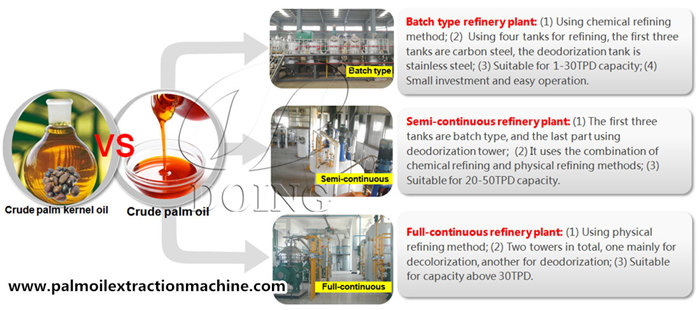

We all heard chemical refining and physical refining classified by refining methods. Likewise, palm oil refinery processing line can be classified to batch type palm oil refinery, semi-continuous palm oil refinery and full-continuous palm oil refinery according to different capacity range. Not only different capacity, but also their process flow & machines used, material consumption, oil loss and final cooking oil grade all different. Let’s see the details one by one.

Henan Doing Company can supply different types of palm oil refining machine

Henan Doing Company can supply different types of palm oil refining machine

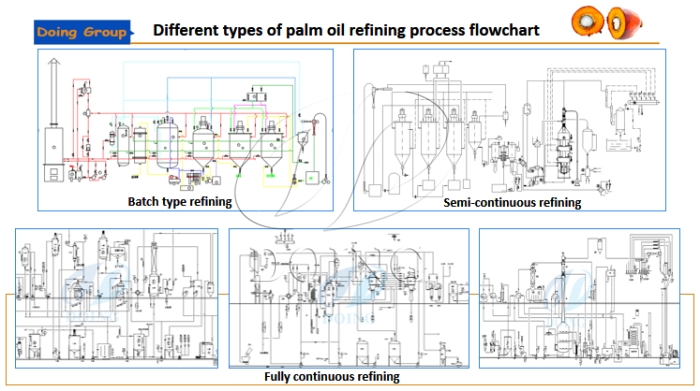

Different types of palm oil refinery plant, different refining process flow:

Palm oil refining processing line contains four steps: degumming, deacidification (neutralization), decolorization and deodorization. In batch type palm oil refinery line, the four steps will process in four different tanks. In semi-continuous refinery line, the deodorization tank is changed to deodorization tower, removing odor more completely and further de-acid by steam to get fatty acid. For full-continuous, not only deodorization tank changed to tower, decolorization tank also changed to tower. And degumming step will together with decolorization step. de-acid part will be together with deodorization step in tower.

Batch type palm oil refining process, semi-continuous palm oil refining process and continuous palm oil refining process

Batch type palm oil refining process, semi-continuous palm oil refining process and continuous palm oil refining process

Different types of palm oil refinery plant, different technology consumption:

Palm oil refining technology more continuous and more automatic, the consumption will be less. Like steam consumption, in batch type refinery, deodorization part steam consumption is 750kg for 1ton per hour capacity; but in continuous refinery, the steam consumption is just 472kg for 1tph capacity. As for water consumption, batch type refining will consume 80kg per ton oil, but continuous refining line will consume 32kg per ton oil.

Different types of palm oil refinery plant, different oil loss;

During palm oil refining process, the main oil loss is from deacidification step. Batch type palm oil refining processing line use alkali and acid neutralized chemical way to remove acid. But continuous palm oil refining processing line use steam to extract fatty acid. In this way, the batch type oil loss will be higher than continuous refining way.

Different types of palm oil refinery plant, different land space;

Batch type palm oil refinery plant project require land space not need too high, but the length of the factory needs to be longer. Continuous refining line need high factory because of the height of the deodorization tower, the length not need much.

Different types of palm oil refinery plant have different factory size requirements

Different types of palm oil refinery plant have different factory size requirements

Besides above difference, there are also many parts and detailed difference for the three type palm oil refinery. If you want to build palm oil refinery plant but no idea how to choose, please no hesitate to contact us Doing Mechanical Equipment Co.,ltd. Our palm oil processing machine engineers will supply more professional palm oil refinery project solution, plant layout and other necessary information.

Leave A Message

If you want to know more information about What is the difference between a batch refinery, semi-continuous refinery, and continuous refinery?. pls kindly leave your phone number, We will back to you ASAP once we got your message.

-

How to start a palm oil milling and processing plant?

How to start a palm oil milling and processing plant?

-

How to start a palm oil processing business in nigeria?

How to start a palm oil processing business in nigeria?

-

How to produce refined vegetable oil from palm kernel oil?

How to produce refined vegetable oil from palm kernel oil?

-

What are the steps in palm oil production?

What are the steps in palm oil production?

-

Why palm oil processing equipment is the key to determining palm oil quality?

Why palm oil processing equipment is the key to determining palm oil quality?

-

What are the mill methods of palm nut oil? What are their different?

What are the mill methods of palm nut oil? What are their different?

-

Why is palm oil deacidified during the refining process? How to perform deacidification?

Why is palm oil deacidified during the refining process? How to perform deacidification?

-

What is the working principle of palm kernel cracker and separating machine?

What is the working principle of palm kernel cracker and separating machine?