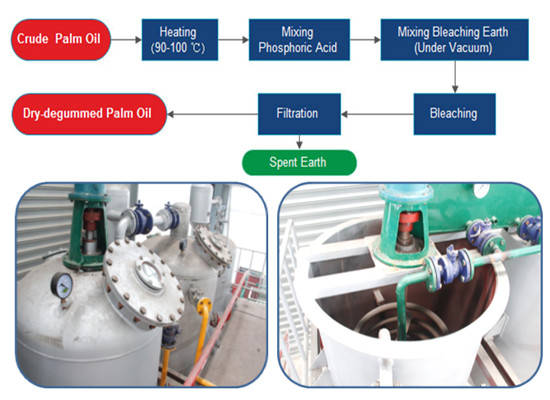

Palm oil refining degumming and deacidification section

Factory direct sale contact number

Palm oil refining degumming and deacidification section is the first step in palm oil refining machine.Palm oil refining degumming and deacidification machine  uses washing method to separate soap residual from mixing oil, providing preparation for next step palm oil refining machine.

uses washing method to separate soap residual from mixing oil, providing preparation for next step palm oil refining machine.

Palm Oil Refining Degumming and Deacidification Section Introduction:

Washing: there is still about 500ppm soap in the neutralized oil from the separator. To remove the remaining soap, during palm oil refining degumming and deacidification process add into the oil about 5~8% hot water, with water temperature 3~5 ℃ higher than the oil generally. To achieve more stable washing effect, add phosphoric acid or citric acid when washing. The re-mixed oil and water in the mixer is heated to 90-95℃ by the heater, and then enters the wash separator to separate the remaining soap and most water. The water with soap and oil enters into oil separator to separate out oil in the water. Further catch the oil outside, and the wastewater is discharged to the sewage treatment station.

Vacuum drying stage: there is still moisture in the oil from the wash separator, and the moisture will affect the stability of the oil. So the oil at 90℃ should be sent to vacuum drier to remove the moisture, and then the dehydrated oil goes to the decoloring process of palm oil refining machine . Finally, pump out the dry oil by canned pump.

Dephosphorization & Degumming Equipment List:

1.Crude oil feed pump

2.Crude oil filter

3.Saving energy heat exchanger

4.Crude oil heater

5.Acidification of delay reaction tank

6.Phosphoric acid dosing pump

7.Multiple effect mixer

uses washing method to separate soap residual from mixing oil, providing preparation for next step palm oil refining machine.

uses washing method to separate soap residual from mixing oil, providing preparation for next step palm oil refining machine.Palm Oil Refining Degumming and Deacidification Section Introduction:

Washing: there is still about 500ppm soap in the neutralized oil from the separator. To remove the remaining soap, during palm oil refining degumming and deacidification process add into the oil about 5~8% hot water, with water temperature 3~5 ℃ higher than the oil generally. To achieve more stable washing effect, add phosphoric acid or citric acid when washing. The re-mixed oil and water in the mixer is heated to 90-95℃ by the heater, and then enters the wash separator to separate the remaining soap and most water. The water with soap and oil enters into oil separator to separate out oil in the water. Further catch the oil outside, and the wastewater is discharged to the sewage treatment station.

Vacuum drying stage: there is still moisture in the oil from the wash separator, and the moisture will affect the stability of the oil. So the oil at 90℃ should be sent to vacuum drier to remove the moisture, and then the dehydrated oil goes to the decoloring process of palm oil refining machine . Finally, pump out the dry oil by canned pump.

Dephosphorization & Degumming Equipment List:

1.Crude oil feed pump

2.Crude oil filter

3.Saving energy heat exchanger

4.Crude oil heater

5.Acidification of delay reaction tank

6.Phosphoric acid dosing pump

7.Multiple effect mixer

Leave A Message

If you want to know more information about Palm oil refining degumming and deacidification section . pls kindly leave your phone number, We will back to you ASAP once we got your message.

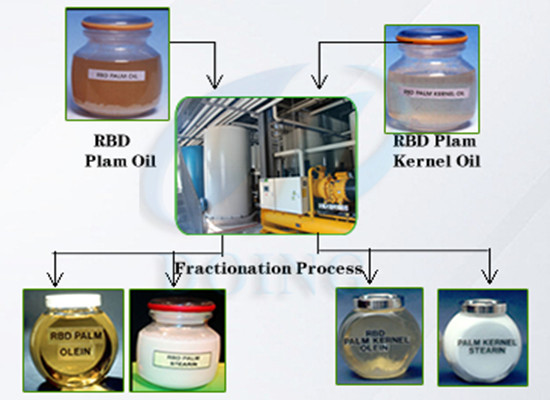

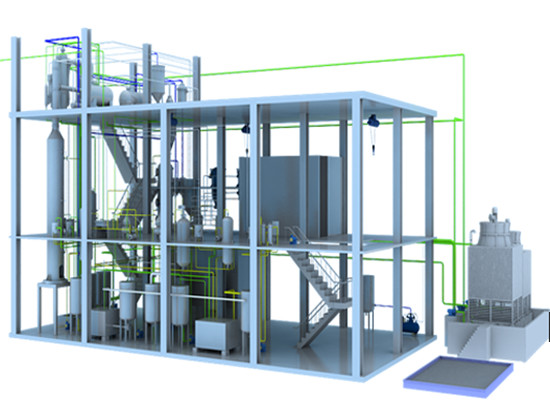

Palm oil refinery

Products

palm oil mill plant projects

Palm Oil Extraction FAQ

-

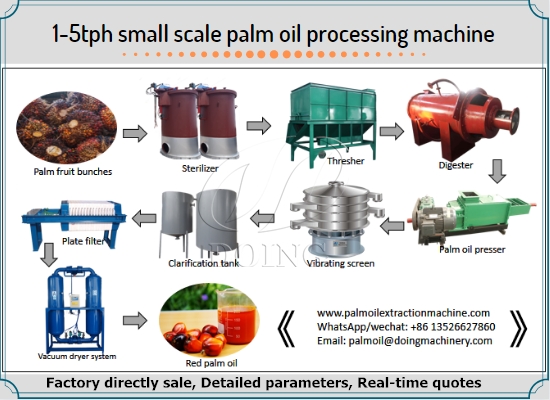

How to start a palm oil milling and processing plant?

How to start a palm oil milling and processing plant?

-

How to start a palm oil processing business in nigeria?

How to start a palm oil processing business in nigeria?

-

How to produce refined vegetable oil from palm kernel oil?

How to produce refined vegetable oil from palm kernel oil?

-

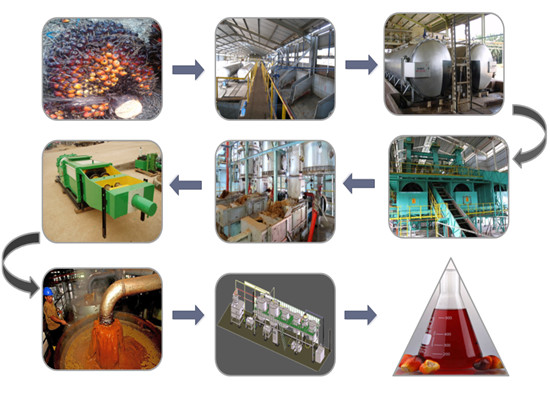

What are the steps in palm oil production?

What are the steps in palm oil production?

-

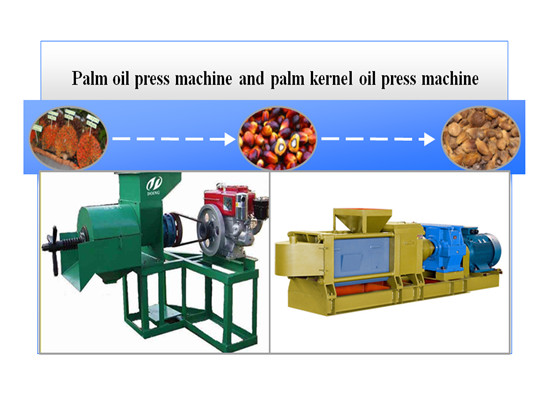

What are the advantages of diesel palm oil presser compared to motor palm oil presser?

What are the advantages of diesel palm oil presser compared to motor palm oil presser?

-

How to optimize palm kernel crushing rate?

How to optimize palm kernel crushing rate?

-

Three Small Machines That Double Your Palm Oil Production: Low-Cost Upgrade!

Three Small Machines That Double Your Palm Oil Production: Low-Cost Upgrade!

-

Why Nigeria palm oil producers prefer modular palm oil production system?

Why Nigeria palm oil producers prefer modular palm oil production system?

recommend products