100tpd palm oil refinery and fractionation plant successfully installed and run in Kenya

This 100tpd palm oil refinery and fractionation plant was ordered by our client in Kenya. It is a turnkey project including factory layout, equipment manufacturing, onsite installing and debugging. Now this 100tpd palm oil refinery and fractionation plant successfully installed and run in Kenya. (Related Project: 30tpd palm oil refinery plant in Congo)

Photos about this project are listed below. Feel free to contact us if need more details of our palm oil mill plant, palm oil refinery plant , palm kernel oil mill plant, and you are also welcome to tell us your plan and let us help you start your own palm oil plant.

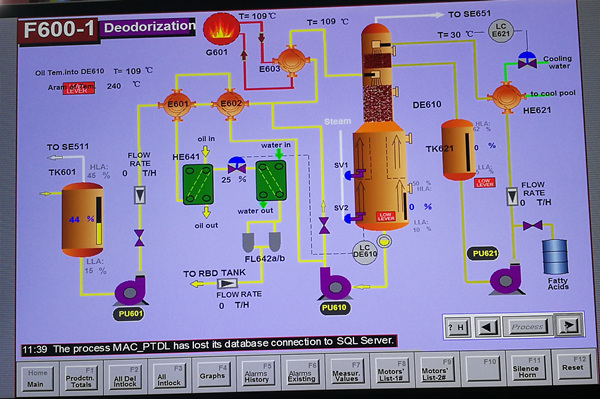

Palm oil degumming & deodorization process

Palm oil degumming & deodorization process

Palm oil degumming & deodorization tower

Palm oil degumming & deodorization tower

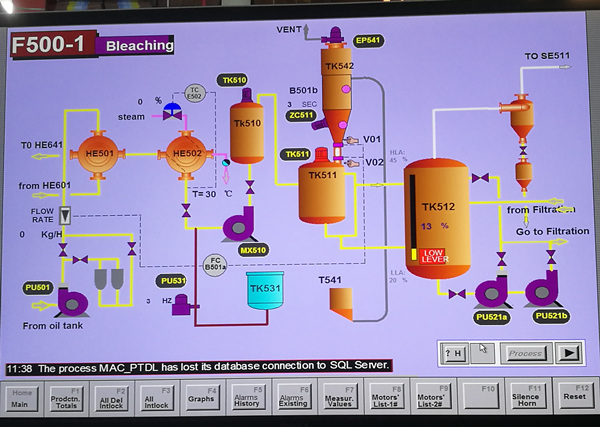

Palm oil decolorization process

Palm oil decolorization process

Palm oil decolorization tower

Palm oil decolorization tower

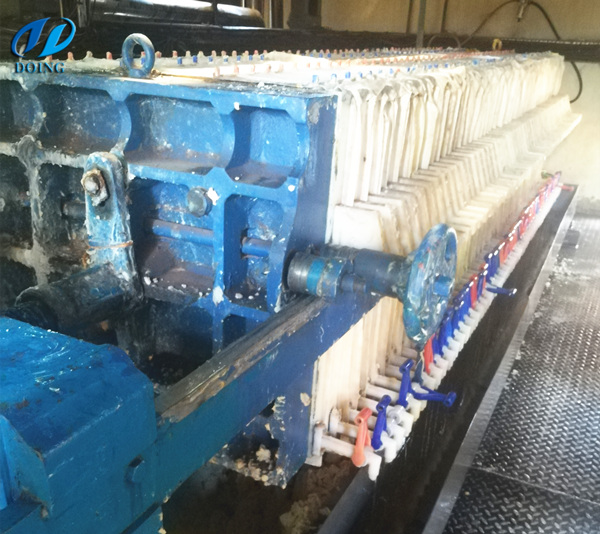

Palm oil filtration machine

Palm oil filtration machine

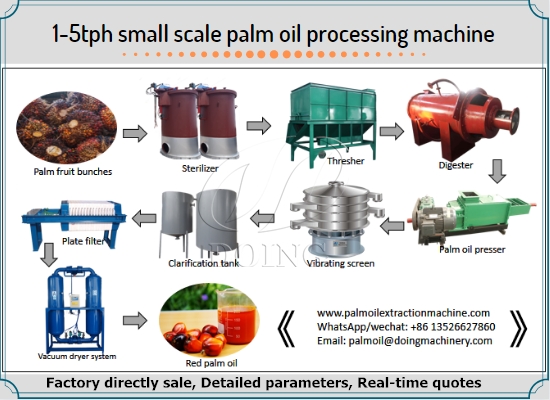

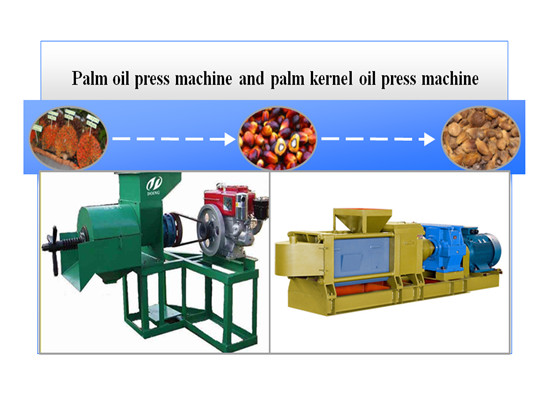

Palm oil refinery plant introduction :

Palm oil refinery plant is one of the important parts of the whole palm oil processing palnt. Palm oil refinery plant refers to conversion of crude palm oil to refined oil involves degumming process,deacidification process,decolorization process and deodorization process.

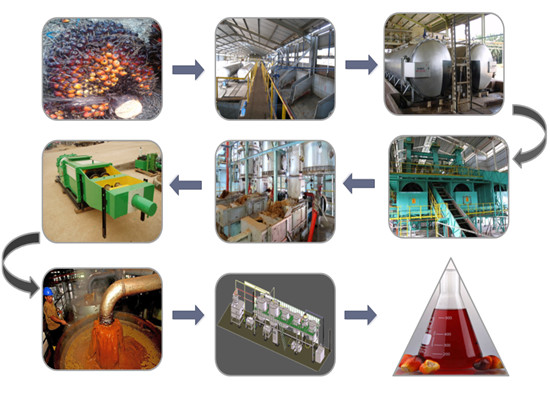

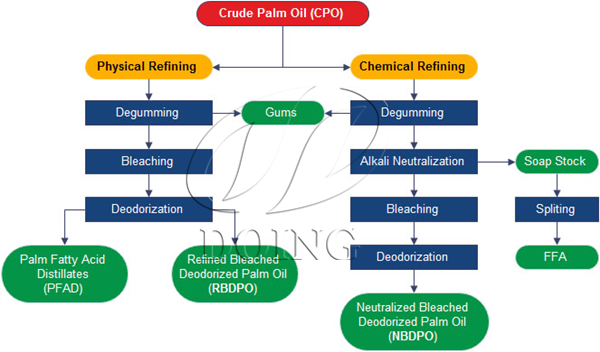

Process flow chart of palm oil refinery plant:

Palm oil refinery process flow chart

Palm oil refinery process flow chart

Main process of palm oil refinery plant:

Degumming and Deacidification Process :

Palm oil degumming and deacidification process uses washing method to separate soap residual from mixing oil, providing preparation for next step palm oil refining machine.

Palm oil decolorizing proces is mainly used to remove oil pigment, residual soap and metal ions during palm oil refining machine.

Palm oil deodorization proces composes of part of crude palm mill processing equipment. It plays an important part in improving oil quality after crude palm oil process.

Palm oil fractionation plant introduction:

Palm oil fractionation process is used to separate the palm olein and palm stearin from the RBDPO (Refined, Bleached, Deodorized Palm oil) produced by physical /chemical treatment. The RBDPO is further passed through the fractionation process to get various grade of palm olein and palm stearin.

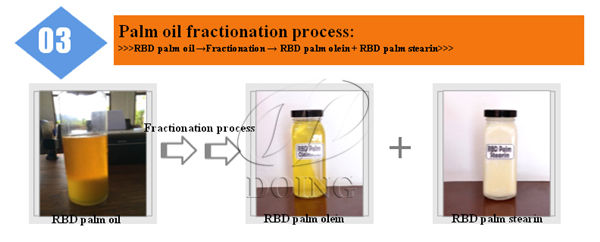

Process flow chart of palm oil fractionation plant:

Palm oil fractionation process flow chart

Palm oil fractionation process flow chart

Applications of palm oil:

Palm oil in the world, is widely used in cooking and food manufacturing. It is used as cooking oil, crispy fat and margarine to use. The same as other edible oil, palm oil can be easily digested, absorbed, and promote human body health.

Leave A Message

If you want to know more information about 100tpd palm oil refinery and fractionation plant successfully installed and run in Kenya. pls kindly leave your phone number, We will back to you ASAP once we got your message.

-

-

-

1tph palm oil pressing machines successfully installed in Lagos, Nigeria

-

-

-

-

500kg/h palm oil and palm kernel oil processing plant project in Ghana

-

-

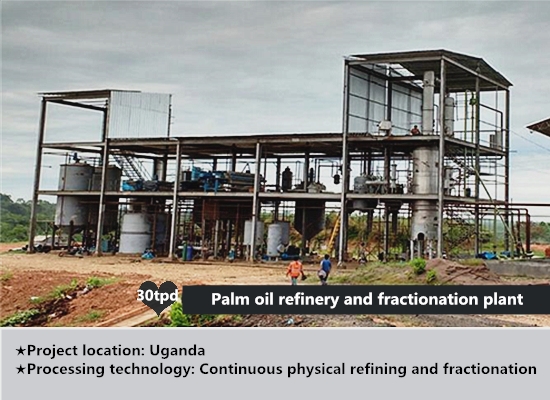

30tpd palm oil refinery and fractionation plant project successfully installed in Uganda

-

Palm kernel crushing and separating machine project in Sierra Leone

-

How to start a palm oil milling and processing plant?

How to start a palm oil milling and processing plant?

-

How to start a palm oil processing business in nigeria?

How to start a palm oil processing business in nigeria?

-

How to produce refined vegetable oil from palm kernel oil?

How to produce refined vegetable oil from palm kernel oil?

-

What are the steps in palm oil production?

What are the steps in palm oil production?

-

How to maintain palm oil making machines?

How to maintain palm oil making machines?

-

What are the environmental or ecological challenges facing the palm oil industry in Malaysia?

What are the environmental or ecological challenges facing the palm oil industry in Malaysia?

-

The anatomy of a commercial palm kernel oil press machine

The anatomy of a commercial palm kernel oil press machine

-

What are the positive and negative impacts of palm oil extraction?

What are the positive and negative impacts of palm oil extraction?