(FFB) Palm fruit oil processing plant

Factory direct sale contact number

Palm oil mill plant

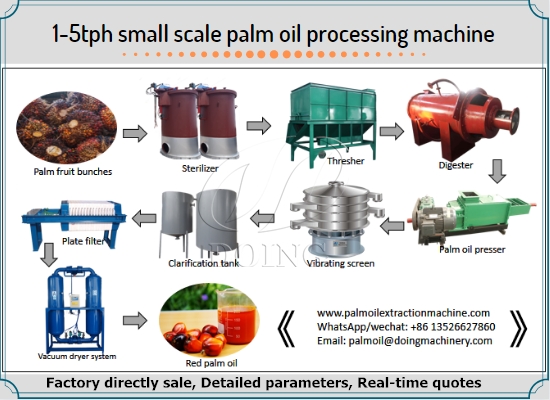

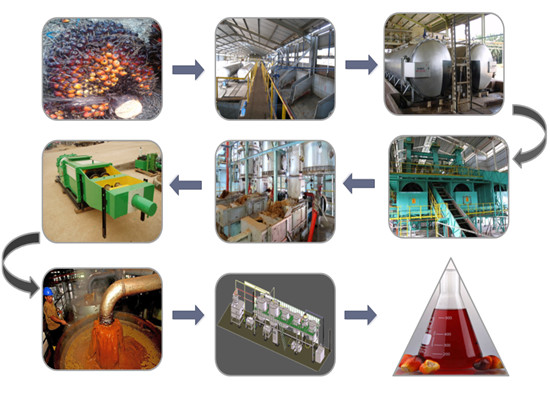

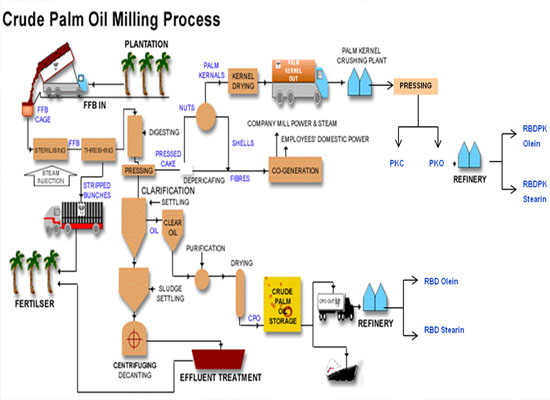

Process flow chart of (FFB) Palm fruit oil processing plant:

Palm fruit oil processing process

1 .Bunch reception

Fresh fruit arrives from the field as bunches or loose fruit,then delivery to palm fruit oil processing plant by truch ,and pass way the weightbridge when cross factory gate.

Palm bunch

Palm fruit

2.Threshing (removal of fruit from the bunches)

The fresh fruit bunch consists of fruit embedded in spikelets growing on a main stem.

Manual threshing is achieved by cutting the fruit-laden spikelets from the bunch stem with an axe or machete and then separating the fruit from the spikelets by hand.

Most small-scale processors do not have the capacity to generate steam for sterilization. Therefore, the threshed fruits are cooked in water.

Whole bunches which include spikelets absorb a lot of water in the cooking process.High-pressure steam is more effective in heating bunches without losing much water.

Therefore, most small-scale operations thresh bunches before the fruits are cooked,while high-pressure sterilization systems thresh bunches after heating to loosen the fruits.

Palm fruit threshing machine

3.Sterilization of bunches

Sterilization or cooking in palm fruit processing plant means the use of high-temperature wet-heat treatment of loose fruit. Cooking normally uses hot water; sterilization uses pressurized steam.

Palm fruit sterilizing machine

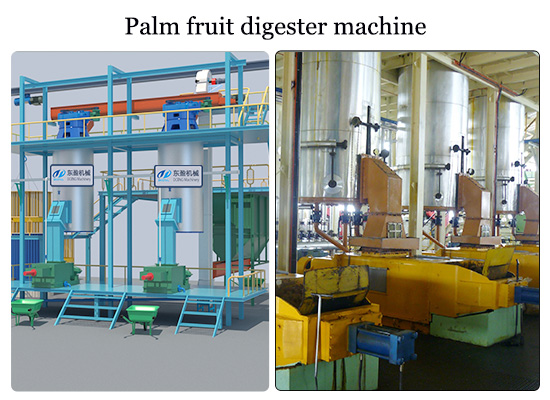

4.Digestion of the fruit

Digestion is one equipment in palm fruit processing plant of releasing the palm oil in the fruit through the rupture or breaking down of the oil-bearing cells.The digester commonly used consists of a steam-heated cylindrical vessel fitted with a central rotating shaft carrying a number of beater (stirring) arms. Through the action of the rotating beater arms the fruit is pounded. Pounding, or digesting the fruit at high temperature, helps to reduce the viscosity of the oil, destroys the fruits’ outer covering (exocarp), and completes the disruption of the oil cells already begun in the sterilization phase.

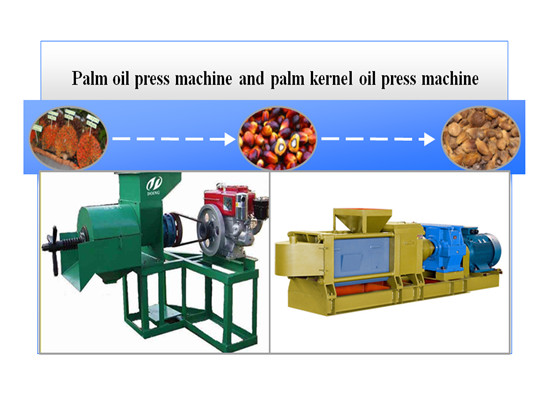

5. Pressing (Extracting the palm oil)

There are two distinct methods of extracting oil from the digested material. One system uses mechanical screw presses, it's for small scale palm oil millThe other called the ‘wet’ method uses hot water to leach out the oil,that's bigger capacity, it'a shydraulic double screw oil press.

(FFB) Palm fruit oil processing plant is a complex process. To design a reasonable technological process, we also consider the following factors in addition to the above principles:

Customized capacity. We customize (FFB) Palm fruit oil processing plant as per your requirement for the capacity.

Flexible usage. The plant can work independently or together with whole palm oil production line.

Know details about how to extract plam oil, Henan Doing Company always supplies professional and customerized (FFB) Palm fruit oil processing plant .

Leave A Message

If you want to know more information about (FFB) Palm fruit oil processing plant . pls kindly leave your phone number, We will back to you ASAP once we got your message.

Palm oil press

Products

palm oil mill plant projects

Palm Oil Extraction FAQ

-

How to start a palm oil milling and processing plant?

How to start a palm oil milling and processing plant?

-

How to start a palm oil processing business in nigeria?

How to start a palm oil processing business in nigeria?

-

How to produce refined vegetable oil from palm kernel oil?

How to produce refined vegetable oil from palm kernel oil?

-

What are the steps in palm oil production?

What are the steps in palm oil production?

-

The role of clarification tanks in high-quality palm oil production

The role of clarification tanks in high-quality palm oil production

-

What makes a sustainable palm oil processing plant?

What makes a sustainable palm oil processing plant?

-

Six Types of Palm Oil Processing Machine and Production Line Revealed: Which Machine Will Suit You?

Six Types of Palm Oil Processing Machine and Production Line Revealed: Which Machine Will Suit You?

-

Palm oil fractionation process

Palm oil fractionation process

recommend products