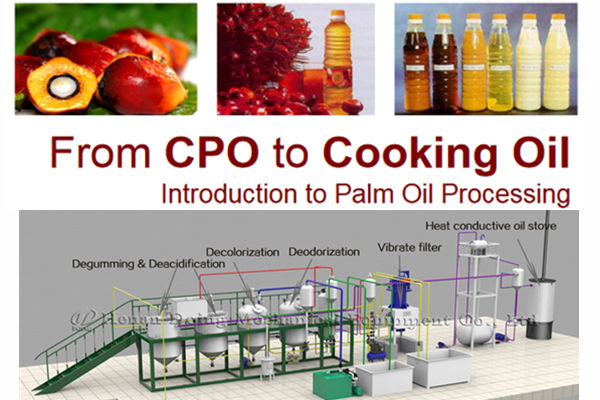

Palm oil refinery plant in nigeria

Palm oil refining machine

Palm Oil Refining Production Line

Palm oil refinery plant is indispensable in palm oil production line. We recommend the most suitable and cost effective palm oil refining production lines to start a local edible oil refining manufacture. Before starting an edible oil refining factory, it is very important to decide scale.In general, palm oil refinery plant divides to 3 types: batch oil refinery plant, semi-continuous oil refinery plant, continuous oil refinery plant. These 3 oil refinery plants are used for different capacity. But the processes in each oil refinery plant are almost the same.

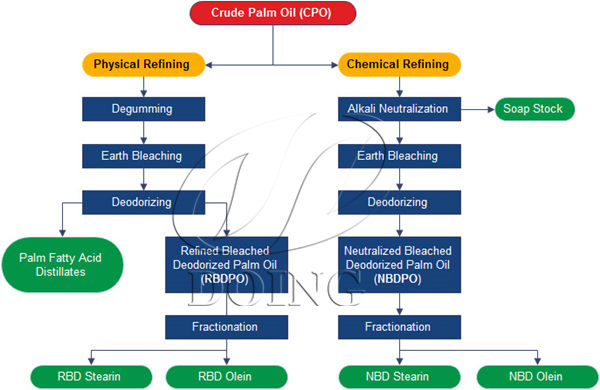

Palm Oil Refining Manufacturing Process

Crude palm oil--Degumming--Neutralize--Decoloring--Deodorizing--Cooling--Final palm oil

Palm oil refinery process flow diagram

Main process of palm oil refinery plant:

1. Degumming Section: Some impurity, such as Phospholipid, gum, and protein, can be dissolved into oil when there is no water, but once there is water in oil, these impurities can be dissolved into water. So, in degumming section, we use the hot water to wash crude palm oil for two-three times to remove these impurities.

2. Neutralizing Section: Crude palm oil contains much free fatty acid, which is harmful for health. Free fatty acid can have reaction with caustic soda. During the reaction, it can be saponified and becomes soap stock, then small soap stock pellets will sink and become sediment and be pumped out. After neutralizing, most of the free fatty acid will be removed out.

3. Decolorization Section: Most of the crude palm oil has deep color because of the pigments, such as carotene, xanthophyll, etc. During batch palm oil refinery machine we use bleaching earth to remove pigments, because bleaching earth has strong adsorption capacity. Then pump palm oil into plate filter to remove bleaching earth, then pigment also will be removed out along with bleaching earth, and oil will be clean and transparent.

4. Deodorizing Section: Pure oil has no smell, but different crude palm oil has their special smell because of some volatile matters, for example the oxide for ketones, aldehydes, hydrocarbons. In deodorizing section of batch palm oil refinery machine, we deliver steam into oil continuously, and make sure steam and oil can fully contacted under high temperature and pressure, then volatile matters can be removed out along with the steam.

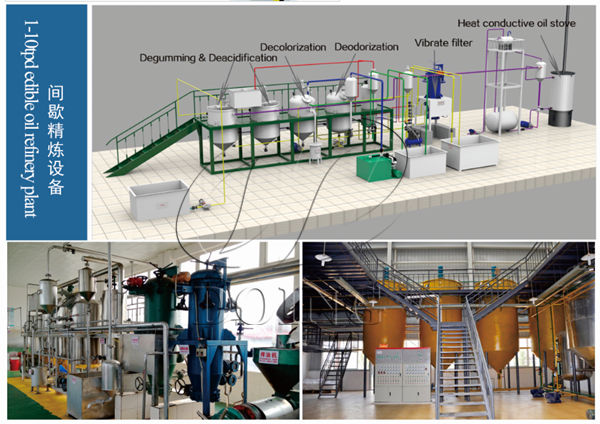

Batch type palm oil refinery plant introduction :

Specification of batch type palm oil refinery plant :

| 1.Batch type palm oil refinery plant | |

| Capacity (Ton/Day) | 1-10TPD |

| Application: | Process almost all kinds of crude oil for edible purpose: vegetable oil, palm oil, castoroil, sunflower oil, rice bran oil, soybean oil, canola oil, cottonseed oil, mustard oil, groundnut oil,etc. |

| Main equipment: | Refining pot, Decoloring pot, Deodorization tank, Steam generator, Vibrate filter,Electricity distribution control, Air compressor |

Pictures show of batch type palm oil refinery plant:

Batch palm oil refinery plant

Semi- continuous palm oil refinery plant introduction :

Specification of semi-continuous palm oil refinery plant introduction :

| 2. semi-continuous palm oil refinery plant | |

| Capacity (Ton/Day) | 10-30tpd |

| Application: | Process almost all kinds of crude oil for edible purpose: vegetable oil, palm oil, castoroil, sunflower oil, rice bran oil, soybean oil, canola oil, cottonseed oil, mustard oil, groundnut oil,etc. |

| Main equipment: | Refining reactor, Decolorization reactor, Vibrating filter, Deodorizing tower, Deodorizedoil pump, Centrifugal water pump, Heat conductive oil furnace |

Pictures show of semi- continuous palm oil refinery plant introduction :

Semi- continuous palm oil refinery plant

Fully- continuous palm oil refinery plant introduction :

Specification of fully continuous palm oil refinery plant:

| 3. Fully continuous palm oil refinery plant | |

| Capacity (Ton/Day) | 30-1000tpd |

| Application: | Process almost all kinds of crude oil for edible purpose: vegetable oil, palm oil, castoroil, sunflower oil, rice bran oil, soybean oil, canola oil, cottonseed oil, mustard oil, groundnut oil,etc. |

| Main equipment: | Washing centrifuge,Vacuum dryer, Decolorization tower, Decolorization oil pump, Platefilter, Deodorization tower, Cooling tower, Thermal oil furnace |

Pictures show of fully- continuous palm oil refinery plant:

Fully-continuous palm oil refinery plant

We are professional manufacturer of edible oil refinery plant.We provide high quality edible oil refinery plant as well as free and skilled technical guidance! Supply various kinds of cooking oil mill plant solutions for different customer depends on your customized demands. Cooking oil refining machine business scope as following:

Leave A Message

If you want to know more information about Palm oil refinery plant in nigeria. pls kindly leave your phone number, We will back to you ASAP once we got your message.

-

How much it will cost to set up a small scale palm oil mill in Nigeria?

-

-

6 Reasons Why Palm Kernel Oil Production in Nigeria is a Smart Investment

-

How can I get palm kernel oil in a palm kernel oil processing plant?

-

-

Why you can invest in palm oil processing business in Ghana?

-

What are reasons that affect the oil yield of palm oil press?

-

How much does it cost to setup a mini palm oil refining plant?

-

How do I start a palm kernel oil processing plant in Liberia?

-

Would it be a profitable business idea to open a palm oil extraction plant in India right now?

-

-

-

1tph palm oil pressing machines successfully installed in Lagos, Nigeria

-

-

-

-

500kg/h palm oil and palm kernel oil processing plant project in Ghana

-

-

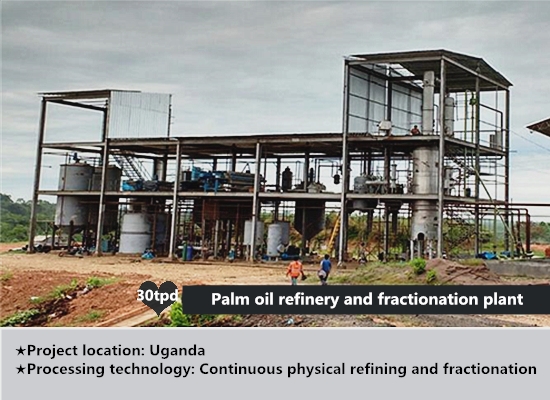

30tpd palm oil refinery and fractionation plant project successfully installed in Uganda

-

Palm kernel crushing and separating machine project in Sierra Leone