New technology palm oil processing machine

The palm oil is the world's second largest edible vegetable oil, only ranking after soybean oil. At present, Malaysia and Indonesia is two largest palm oil producing countries in the world. Besides, there are many palm oil mills in Africa, such as Nigeria, Ethiopia, Congo, Ivory Coast ect.

Our company is professional in manufacturering palm oil processing machine for years. At present, we research and design a new technology of palm oil extraction machine , based on our rich experience in palm oil mill.

The following is detail introduction of our new technology- palm oil processing machine .

Work flow of new technology palm oil processing machine :

1. Fresh palm fruit bunch in palm oil machine :

FFB means fresh palm fruit bunch. Palm oil fruit can be harvested all the year round. After cutting from palm trees, fresh palm fruit bunch must be processed within 2days. Or the acid value will be high and affect the final palm oil quality.

2, Threshing section of palm oil processing machine :

Threshing is used to separate palm fruit seeds and the empty palm fruit bunch.

New product palm fruit threshing machine

3. Drying section of new technology palm oil processing machine :

The purpose of drying is to adjust the moisture and tempreture of palm fruit, then you can press palm oil esaily.

Drying section of new technology palm oil precessing machine

4. Crushing section of new technology palm oil processing machine :

This section is mainly to separate palm fruit and palm kernel, so the oil is extracted easily and effectively. The palm kernel will be transported to nut polishing system directly.

Crushing section of new technology palm oil processing machine

5. Palm fruit pressing section of new technology palm oil processing machine :

To extract the crude palm oil from the palm fruit.

Pressing section of new technology palm oil processing machine

The filter is used to remove the impurities in the crude red palm oil.

Filtering section of new technology palm oil processing machine

Crude palm oil

Advantages of new technology palm oil processing machine :

B: No pollution, new technology adopts drying method without steam, which reduces final water waste; No sewage treatment machines, less space, less cost;

C: Empty bunches or kernel to burn and supply hot air to dyer. Fully use of all materials during production.

D: Cake has low moisture content, can be directly used to process animal feed.

E: Whole palm oil mill takes smaller place than traditional method;

F: Generate electricity by the system itself, solve electricity problem.

Whole system has limits of capacity: 3tph-5tph -10tph-20tph;This system is mainly proper for small palm oil mill;

Comparison of traditional technology and new technology of palm oil processing machine :

1. Work flow of new technology palm oil processing machine :

FFB-Threshing-Drying-Crushing-Pressing-Filtering-Palm oil

↓

Empty palm bunches-boiler

2.Brief introduction of traditional palm oil processing machine :

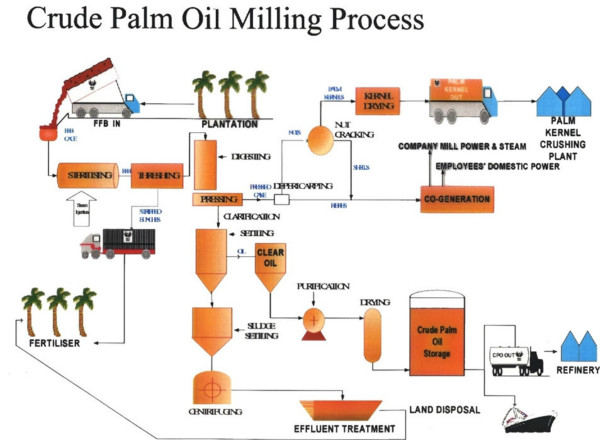

Raw materials storage section----Sterilizing section----Threshing section----Pressing section----Clarification section----Crude oil storage and transportation section----Fiber separation section----Kernel recovery section----Sewage treatment section

Crude palm oil milling process

The traditional technology is proper for bigger capacity palm oil mill, like 30tph, 60tph, 80tph and above. Unlike traditional process, we have designed a new technology specially for smaller capacity palm oil mill, like 3tph-5tph-10tph-20tph.

| Traditional | New | |

| Cost | High | Low |

| Space | Large | Small |

| Capacity | ≥ 30tph | < 30tph |

| Process | With steam | Without steam |

| Consumption | High | Save energy |

| Pollution | Waste water | No waste water |