Refining into refined,bleached and deodorised rbd palm oil

Palm fruit

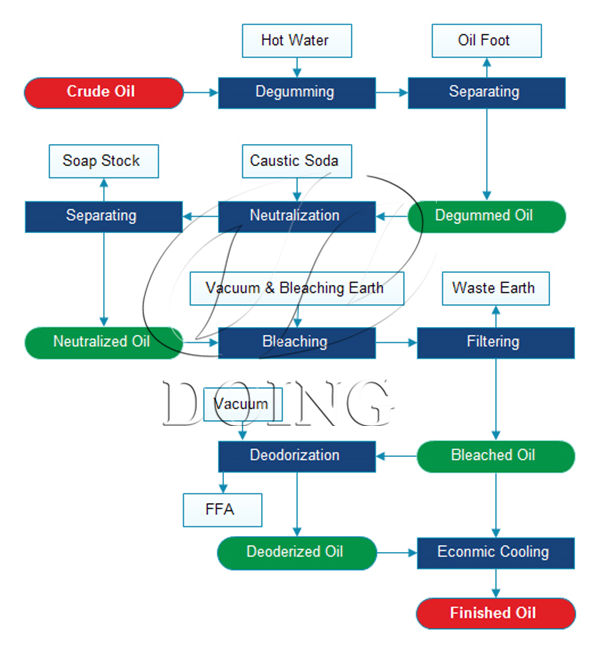

In degumming, the gum and fatty acid in crude palm oil and crude palm kernel oil are separated together with other impurities such as trace minerals, copper and iron by the application of phosphoric acid.

In bleaching, the oil is mixed with bleaching earth (bentonite calcium) in a vacuum room to remove impurities and colour pigments in the palm oil.

In deodorizing, the odour and taste of the oil are removed when the oil is steamed at high temperatures of between 240°C to 260°C and then cooled to room temperature.

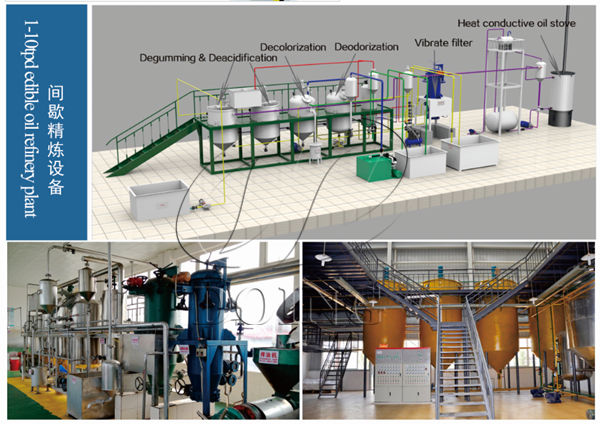

Small scale palm oil refining machine

|

Capacity (Ton/Day): |

Batch type palm oil refining machine: 1-20tpd Semi-continuous palm oil refining machine: 20-50tpd Fully continuous palm oil refining machine: 50-1000tpd |

| Applications: |

Process almost all kinds of crude oil for edible purpose: vegetable oil, palm oil, castor oil, sunflower oil, rice bran oil, soybean oil, canola oil, cottonseed oil, mustard oil, groundnut oil, etc. |

| Machine Cost: |

$21,000~$655,000 (the exact price is based on capacity and other requirements of each equipment) |

Related question of aplm oil refining machine:

The Purpose of palm oil refining machine:

The crude palm oil getting from oil pressing or the palm kernel oil getting from pressing machine, extraction plant certainly contain different amounts of non-oil impurities, such as mechanical impurities, free fatty acid, colloid, pigment, stink substances, moisture and wax, etc. These impurities will directly change the oil’s color, smell, taste, transparency, stability degree and nutrition, which not only affect the edible value, but also make the oil easy to deteriorate when storing.

The purpose of palm oil refining process is to remove all kinds of impurities, and make the least damage to the neutral oil and natural antioxidants (tocopherol), so as to produce high quality oil produces.

Provide the Best Solution of palm oil refinery plant:

Referring to oil refining, the character of impurities contained in crude oil, and the purpose of refined oil must be concerned. Henan Doing Company will customize the oil refinery process and solution for each of customer depending on their specific situation and needs.

Palm oil refinery process includes degumming process, deacidification process, decolorization process, deodorization process, and dewaxing process, etc. We will design the edible oil refining process depending on the quality requirements of refined oil.

Choose the Most Suitable Refinery Methods for You

We will choose the refinery methods according to the different requirements of different types of oil. Both technical and economic effects are taken into account while plan the refinery plant, so that to build the best cooking oil refinery line which can remove the most completely unwanted and harmful impurity under the condition of minimum oil loss.

Crude palm oil process flow diagram

Offer customized refining solution according to different oil varieties (soybean, peanut, cottonseed, rapeseed, vegetable seeds).

The application and qualification of refined oil. In addition to various levels of edible oil, there are base oil, drying oil, paint oil, pyrolysis oil, hydrogenated oil, salad oil, cooking oil, vegetable shortening and margarine, etc. Customized oil refining process will be offered to meet the quality requirements of different oil.

Ensure the process of refining workshop is adapted to the production capacity of your enterprise. Continuous refining plant is suggested for production of large capacity, while batch or semi-continuous types are more suitable for medium and small oil refining workshops.

Others, such as the reliability of the equipment and technology, labor productivity, the consumption rate of auxiliary materials, steam, water and electricity.

Feel free to contact us through the below contact form to get more details of our oil material processing projects. Send us your requirements so we can offer you the tailor made solutions according to your situation. You will get a quick reply in one business day!

Our palm oil refining machine is characterized mainly by simple design, operator friendliness, low power consumption, and high palm oil yield capacity. Our customers are very satisfied with them. If you are looking for the palm oil refining machine, please feel free to contact us now! We provide high quality palm oil refinery plant as well as free and skilled technical guidance!

Leave A Message

If you want to know more information about Refining into refined,bleached and deodorised rbd palm oil. pls kindly leave your phone number, We will back to you ASAP once we got your message.

contact us

Palm Oil Extraction FAQ

-

How to start a palm oil milling and processing plant?

How to start a palm oil milling and processing plant?

-

How to start a palm oil processing business in nigeria?

How to start a palm oil processing business in nigeria?

-

How to produce refined vegetable oil from palm kernel oil?

How to produce refined vegetable oil from palm kernel oil?

-

What are the steps in palm oil production?

What are the steps in palm oil production?

-

Why palm oil processing equipment is the key to determining palm oil quality?

Why palm oil processing equipment is the key to determining palm oil quality?

-

What are the mill methods of palm nut oil? What are their different?

What are the mill methods of palm nut oil? What are their different?

-

Why is palm oil deacidified during the refining process? How to perform deacidification?

Why is palm oil deacidified during the refining process? How to perform deacidification?

-

What is the working principle of palm kernel cracker and separating machine?

What is the working principle of palm kernel cracker and separating machine?

Products